Properties of PTFE - Polytetrafluoroethylene

Polytetrafluoroethylene PTFE is high performance Engineering Plastics having unique properties:

- PTFE is chemically Inert & nonreactive to almost all known chemicals.

- PTFE has Excellent Thermal Resistance upto 260°C

- PTFE is Non-adhesive, not bondable & has Anti Stick Properties

- PTFE is material with Exceptionally low coefficient of friction

- PTFE has Outstanding Electrical Insulation properties

- PTFE has Excellent weathering resistance

Due to unique properties, PTFE Products are used in Chemical Process, Pharmaceutical, Electrical & Electronic Industries, Thermal & Automatic Power Plants, Railways & Defense Sectors, practically in all kind of industries.

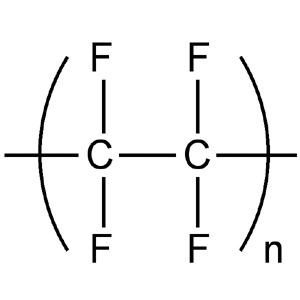

Chemical Structure of PTFE Polytetrafluoroethylene

Poly Tetra Fluoro Ethylene is a linear polymer free from any significant branching have chemical structure as:

In PTFE, due to large fluorine Atom, PTFE Molecule takes up a twisted zigzag, with the fluorine atoms packing tightly in a spiral around the Carbon-carbon skeleton. This compact interlocking of fluorine atoms lead to a PTFE molecule of great stiffness leading ultimately high crystalline melting point @ 327°C, thermal stability & electrical insulation properties. Due to strong & stable bond between carbon & fluorine atom, PTFE molecule processes outstanding chemical inertness.

PTFE polymer is being produced worldwide on commercial Basis by many Chemical industries under different registered trade names such as Du Pont - Teflon, Asahi - Fluon, Hoecst - Hostaflon, Daikin - Ployflon, HFL - Hiflon, GFL - Inoflon, Halogen - F4, Shandong - DF, Shanghai - 3F etc.

Properties, Selection Guide & Applications of PTFE and Filled PTFE Products

PTFE is available in virgin & filled compounds to improve the basic characteristics to match very diverse applications & optimization for specific end uses.

The grade of PTFE is selected from Virgin & Filled grades of PTFE, based on required property for required service conditions / applications. The selection guide elaborates various grades of PTFE & Filled PTFE, filler content in PTFE, basic properties & relevant service conditions / End applications.

| Grade | Filler Content by Weight % | Standard Series | Properties | Applications |

| Virgin PTFE | - | Yes |

• Hygienic • Excellent chemical resistance • Outstanding electrical properties • Excellent flexural properties |

Gaskets, Bellows, food / contact & medicine / human consumption applications. |

| Chemically Modified PTFE | - | Yes |

• Less Creep. • Improved Permeation Resistance • Smoother Surfaces • Less Porous • Better High Voltage Insulation • New Fabricating Versatility with welding |

Pumps, Diaphragms, Ball Valve Seats, Components of Mechanical Seals, Dipped Pipes for reaction vessels, Vessel Lining |

| Glass Filled PTFE | 15 - 25 | Yes |

• High compressive strength • Excellent chemical resistance • Improved wear resistance under load & permanent deformation |

Ball valve component, bridge bearing pads, ship launching pads, pipe supporting pads. |

| Glass + MoS2 Filled PTFE | 5/15 + 5 | Yes |

• High compressive strength • Excellent chemical resistance • Improved wear resistance under load & permanent deformation • Improved frictional properties |

Low torque valve components |

| Carbon/coke Filled PTFE | 25 – 35 | Yes |

• High compressive strength • Improved wear resistance under load & permanent deformation • Better thermal / electrical conductivity |

Rider and piston rings of air compressor |

| Graphite Filled PTFE | 15 | Yes |

• High compressive strength • Improved wear resistance under load & permanent deformation • Better thermal / electrical conductivity. • Good chemical resistance • Improved frictional properties. |

Shaft bearings in chemical high speed Chemical pumps. |

| Bronze Filled PTFE (oxidized / Non-oxidized) |

40 - 60 | Yes |

• High compressive strength • Excellent wear resistance improved under load & permanent deformation • Better thermal / electrical conductivity. • Good chemical resistance • Very low cold flow. |

Wear Strips Machine tool liners, hydraulic seals. |

| Bronze plus, Molybdenum Disulphide Filled PTFE | 40/55+ 5 | Yes |

• Improved fictional properties • High compressive strength • Excellent wear resistance improved under load & permanent deformation • Good thermal / electrical conductivity. • Very low cold flow. |

Hydraulic seals. |

- 7 – 14 % Aluminum Oxide (Alumina) Filled PTFE

- 5 – 15 % Mineral / Wallastonite / Calcium Silicate filled PTFE

- 5 -10 % Calcium Fluoride Filled PTFE

- 50 % Stainless Steel Filled PTFE

- 5 – 10 % Mica Filled PTFE

- 10 – 20 % Peek Filled PTFE

- 0.1 – 0.2 % MoS2 Filled PTFE

- Pigmented PTFE

- Anti Static PTFE

- Conductive PTFE

There are many popular filled grades PTFE Products brand-named as Trexonn, Turcite B, Rulon AR, Rulon AJ Gold having specific properties, designed for specific service and applications.

Hindustan Nylons manufactures all these grades of PTFE Products with specific filler contents against specific order on request subject to Minimum Order Quantity.

Comparison of Virgin PTFE & Reprocessed / Recycled PTFE (Properties & Performance):

PTFE is high performance Engineering Polymer having versatile properties to face extremely tough service conditions. The most typical properties are:

- Chemical Inertness to all known chemicals.

- Wide operating temperature range – Cryogenic (-260°C) to +260°C.

- Excellent electrical insulation properties.

- Lowest frictional characteristic.

As always, price is critical commercial consideration, even for this high end engineering polymer, though meant for premium performance, facing extreme service conditions. As using reprocessed PTFE, price factor is compensated at the cost of performance, Hindustan Nylons does not produce Products from Reprocessed / Recycled PTFE.

The physical properties & performance of components made out of Virgin PTFE & Reprocessed PTFE are significantly different. The typical properties & service conditions - affected by use of Reprocessed PTFE are illustrated:

| S.No. | Property | Service Condition/ Application |

| 1 | Poor Tensile Properties & Elongation | Cannot be used for high Tensile Applications like expansion joints. |

| 2 | Lower Compressive Strength | Cannot be used for Compression Loads like Bridge Bearings |

| 3 | Lower Impact Strength, more brittle | Cannot be used for Impact Loads |

| 4 | Inferior flexible modulus, Harder | Poor flexibility cannot be used for sealing applications like Diaphragms of Pumps & Valve. |

| 5 | More Creep, more Deformation under load | Cannot be used for constant load applications like Gasketing |

| 6 | Inferior permeability Resistance, more Porosity & Void contents | Cannot be used for constant chemical contact like Liners. |

| 7 | Reduction in Abrasion Resistance | Wears fast in frictional service conditions like Valve Parts, Mechanical Seals |

| 8 | Lower Dimensional stability | Cannot be used over wide temperature range |

| 9 | Lower Thermal Resistance | Cannot be used for Service conditions more than 175°C temperature |

| 10 | Poor Dielectric Strength | Cannot be used for tough Electrical environment like electric insulators. |

| 11 | High Dielectric Constant | Cannot be used in static electrical fields. |

Reprocessed PTFE - Not for Extremely Critical Environments

As PTFE is high performance polymer & typically used in extreme environments, for completely fail safe applications. By using reprocessed PTFE, the reliability of this high end engineering polymer is adversely affected & the product cannot be guaranteed for extreme service conditions.

Unreliable Performance of Reprocessed PTFE

The performance of reprocessed PTFE is highly unreliable, not guaranteed for critical applications, as the physical properties are substantially detoriated in incremental proportion of content of reprocessed PTFE Resin. Virgin PTFE is absolutely fool proof & failsafe for service conditions falling within physical properties range.

Pre-mature failure of Reprocessed PTFE Parts

Due to poor physical properties of reprocessed PTFE, the products are subjected to Pre-mature failure & plant may go into repetitive maintenance leading to production/ monetary loss.

Accidents-Prone Reprocessed PTFE

Most of PTFE parts are used in extremely critical service conditions such as highly corrosive media, high voltage electrical conditions, radiation environment etc. However, due to un-reliable / un-known / poor properties of reprocessed PTFE - parts may not be able to face these extreme conditions & may fail, leading to accidents, medical emergency & threat to human life, in addition to damage to plants & machinery

Cheap but extremely uncertain prices of Reprocessed PTFE

Though, prices of Virgin PTFE products are on higher side, those will be almost same all over the world. However, prices of reprocessed PTFE, depends upon percentage of reprocessed Resin mixed & the prices will vary over the wide range of span from processor to processor, country to country. The percentage of reprocessed PTFE cannot be verified in laboratory & can be judge only on the basis of values of physical properties.

Comparison of Physical Properties - Virgin PTFE Vs Reprocessed PTFE

| Property | Virgin PTFE (100%) | Reprocessed PTFE (25% Repro+75% Virgin) |

| Appearance | White | Off White |

| Density | @ 2.15 | @ 2.17 |

| Void Content (%) | 0.5 – 1 | 2 |

| Tensile Strength (kgf/cm²) | 225 Min | 175 Max |

| Elongation (%) | @ 300 Max | @ 200 Max |

| Compressive Strength (kgf/cm²) | 40 Min | 20 Max. |

| Deformation Under Load (%) | 10% | 25% + |

| Flexible Modulus (kgf/cm²) | 3500 – 6300 | 18000 |

| Continuous Service Temperature at Atmospheric Pressure (°C) | 250 Max. | 175 Max. |

| Melting Point (°C) | 342 | 327 |

| Dimensional Stability (%) | 0.2 – 3 Max | 5 Min |

| Dielectric Strength (Kv/mm) |

24 Max. |

15 Max. |

| Dielectric Constant | 2.05 – 2.1 | > 15 |

Note: The Physical Properties are substantially detoriated in incremental proportion of content of Reprocessed PTFE Resin.